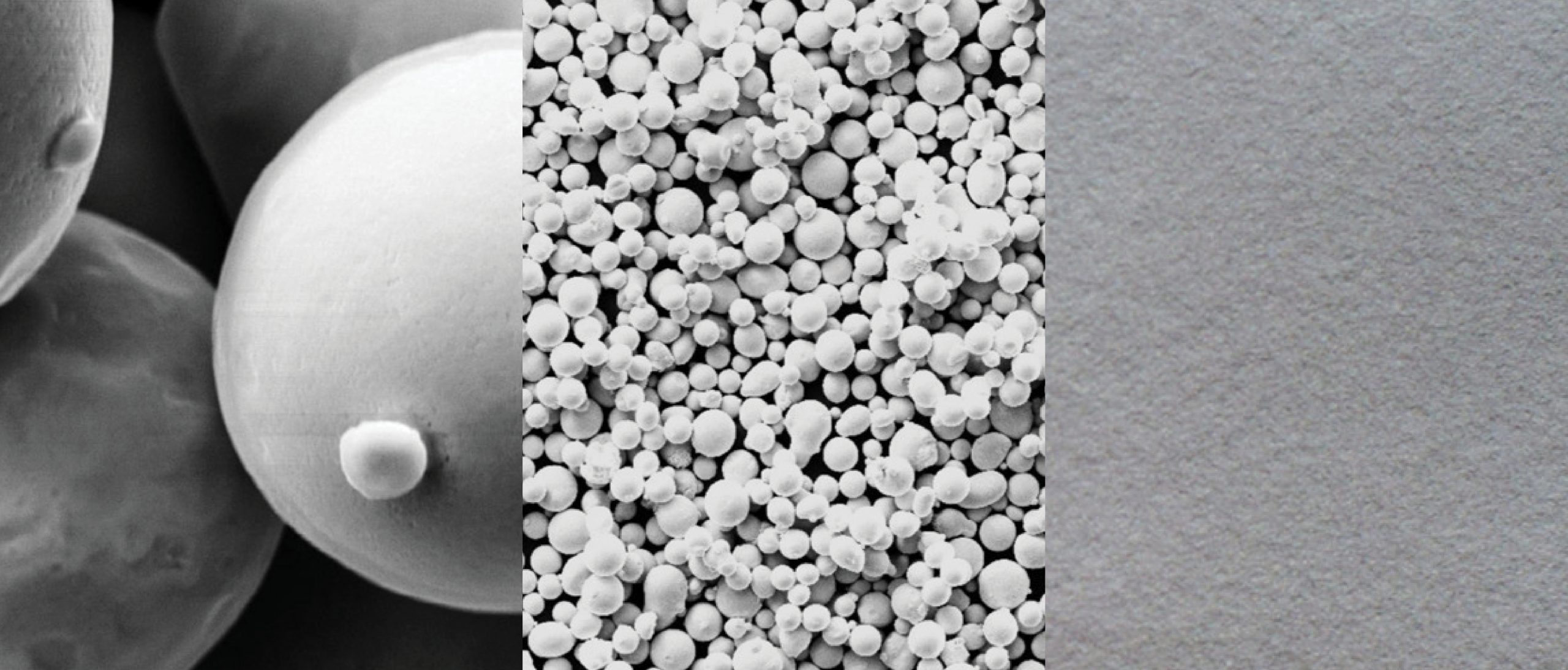

The Modelling and Simulation Research Group and collaborators have recently published a paper investigating a new high-entropy alloy (HEA). The team, led by Assistant Professor Mauricio Ponga, designed the material’s composition using atomic-level computer simulations to find an optimal mixture of elements. This novel material combines cobalt, chromium, iron, molybdenum, and niobium atoms. It was manufactured using an additive manufacturing technique called cold spray. “Cold spray is an additive manufacturing technique where particles are accelerated to velocities as high as 1000 m/s. Once the particles reach a substrate, they get deposited due to severe plastic deformation”, says Ponga.

The team found that the high-velocity impact of the microparticles generates dynamic recrystallization of its grains. This means that the material’s microstructure can be changed drastically due to the stresses developed during the impact. As a result, the novel material exhibits grains with various sizes ranging from billionths to millionths of a metre (~1 nm to ~1 micron). The resulting alloy is one of the strongest HEAs known. It is mechanically stronger than most alloys commercially available, including high-strength steels.

By understanding how material properties work at the atomic level, Dr. Ponga’s group is dedicated to finding new ways to develop and manufacture materials with specific properties. By using computer modelling to design materials at the smallest level, they are investigating what is essentially the creation of custom materials, tailor-made to fit specific applications.

The paper “Mechanical and microstructural properties of a CoCrFe0.75NiMo0.3Nb0.125 high-entropy alloy additively manufactured via cold-spray” can be found at https://doi.org/10.1016/j.jallcom.2021.162309.